Blog

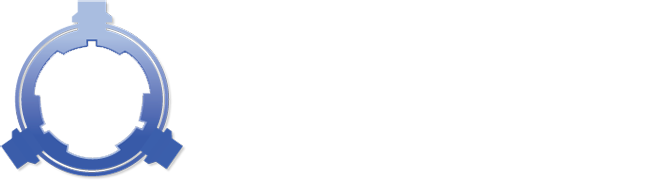

Top 10 Uses of Air Actuator in Modern Technology?

Air actuators have become essential components in modern technology. They convert compressed air into motion, enabling precise control in various applications. From manufacturing to robotics, air actuators play a vital role. They offer numerous advantages, such as efficiency and speed.

In aerospace, air actuators help control flight surfaces. This enhances maneuverability and ensures safety. In automotive applications, they provide reliable actuation for braking systems. Efficiency is crucial here, as safety is non-negotiable.

Despite their benefits, air actuators present challenges. They can be less effective in extreme temperatures. Maintenance is necessary to ensure consistent performance. Understanding these limitations is essential for engineers and designers. Balancing efficiency and reliability remains a constant goal in the field.

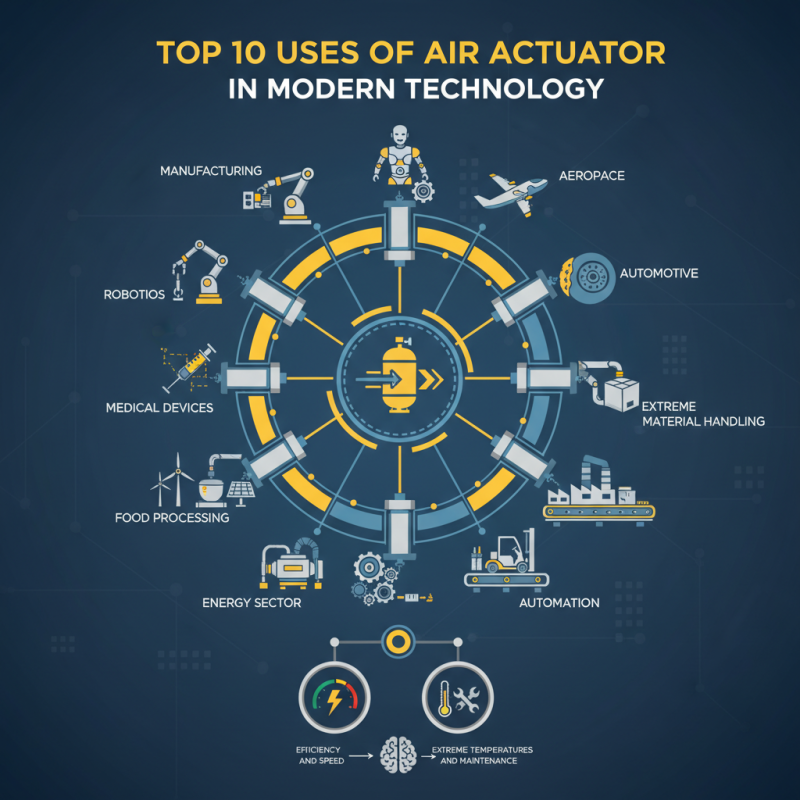

Key Applications of Air Actuators in Robotics and Automation

Air actuators are pivotal in robotics and automation. They provide smooth and efficient movement. These devices convert compressed air into mechanical motion. This is crucial in environments requiring precision.

In robotic arms, air actuators enable flexible movements. For instance, they help in grasping objects of various shapes. Their lightweight design allows for easy integration. However, air leaks can reduce efficiency. Designers must address this to enhance performance.

In assembly lines, air actuators drive conveyor belts. They move products seamlessly from one stage to another. This increases productivity but also poses risks. A sudden stop can disrupt the entire process. Balancing speed and safety is essential for optimal operation.

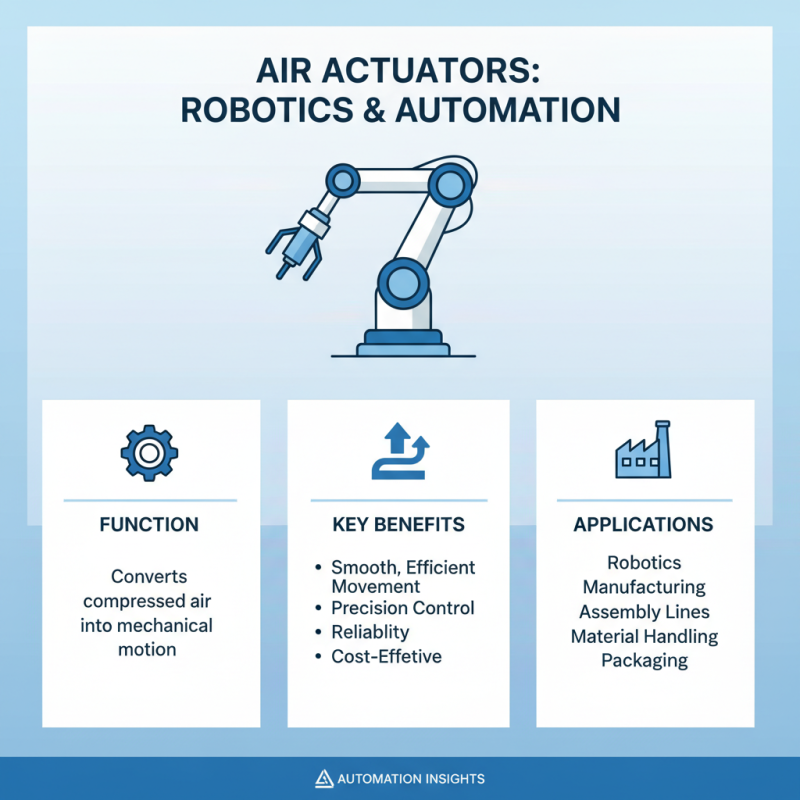

Enhancing Industrial Machinery Performance with Air Actuators

Air actuators play a crucial role in enhancing industrial machinery performance. These devices convert compressed air into mechanical energy, enabling precise control and efficient operation. According to the International Society of Automation, 60% of manufacturing plants now leverage pneumatic systems. This rise underscores the importance of air actuators in streamlining production processes.

One significant advantage is their ability to reduce downtime. With a response time of less than 100 milliseconds, air actuators can quickly adapt to changing demands. However, not all systems are designed equally. Some industries face challenges in maintaining optimal pressure levels. This can lead to inconsistent performance, reminding engineers to constantly monitor their setups.

Moreover, air actuators contribute to energy efficiency. A recent report from the American Institute of Chemical Engineers highlights that replacing hydraulic systems with pneumatic alternatives can lower energy consumption by up to 30%. Yet, transitioning requires careful planning. Unforeseen costs can arise during retrofitting processes, indicating the need for proper assessment before implementation.

Top 10 Uses of Air Actuator in Modern Technology

| Use Case | Description | Advantages |

|---|---|---|

| Robotics | Utilized in robotic arms for precise movement and handling tasks. | High precision, fast response time. |

| Automated Manufacturing | Enables automation in assembly lines and machine operations. | Increases efficiency, reduces labor costs. |

| Material Handling | Used in conveyor systems for moving goods. | Enhanced safety and reduced manual handling risks. |

| Valves and Control Systems | Air actuators control the flow of liquids and gases. | Improved control over systems and process parameters. |

| Aerospace Applications | Used in aircraft systems for landing gear and flaps. | Lightweight and reliable operation. |

| Automotive Industry | Employed in power steering and braking systems. | Enhanced performance and driver experience. |

| Textile Machinery | Used for automatic fabric handling and machine control. | Increased production speed and consistency. |

| Food Processing | Utilized in packaging and production line automation. | Improved hygiene and efficiency. |

| Construction Equipment | Air actuators power various construction tools and machinery. | Robustness and adaptability in diverse conditions. |

| Home Automation | Applied in smart home systems for window and door operations. | Convenience and enhanced energy efficiency. |

Air Actuators in Automotive Systems: Efficiency and Functionality

Air actuators play a vital role in modern automotive systems. They provide efficiency and functionality across various applications. These devices convert compressed air into mechanical motion, making them ideal for tasks like opening and closing valves or adjusting suspension systems. In a car, they can control airflow, enhancing engine performance.

However, there are challenges. The reliability of air actuators can vary based on temperature and humidity. This variability can lead to inconsistent performance. Maintenance is essential, as dirt and moisture can impair functionality. Yet, the integration of air actuators has transformed the driving experience. They allow for smoother transitions and precise adjustments in numerous systems.

In electric vehicles, air actuators can optimize energy consumption. They can precisely control components without drawing excessive power. Despite their advantages, there is still room for improvement. Developers must focus on increasing durability and reducing response times. Ongoing innovations could make these devices even more effective and reliable. The future of air actuators in automotive systems looks promising, but challenges remain.

Top 10 Uses of Air Actuator in Modern Technology

This chart illustrates the various applications of air actuators across different modern technologies, highlighting their efficiency and functionality. The data reflects the percentage use of air actuators in various sectors.

Integration of Air Actuators in Aerospace Technology

Air actuators play a vital role in aerospace technology. They provide essential movement and control in aircraft systems. These actuators use compressed air to create motion. This system is lightweight and efficient, making it ideal for aircraft applications.

In modern aircraft, air actuators are found in flight control mechanisms. Flaps, ailerons, and rudders can be adjusted swiftly. This enhances the aircraft's performance and handling. Additionally, pneumatic systems are used for landing gear operations. Quick deployment is crucial for safety during landings.

However, there are challenges with air actuators. They can be sensitive to temperature changes. Condensation may affect their performance. Engineers must continuously refine these systems. Improvements are necessary to ensure reliability and safety. Exploring these imperfections leads to better designs in the future. Constant innovation is needed in aerospace technology, and air actuators remain a key focus area.

Innovative Uses of Air Actuators in Consumer Electronics

Air actuators are transforming consumer electronics. They provide precise movements in devices, improving user experience. By using compressed air, they enable smooth operations for various gadgets. For example, air actuators can power touchless control in appliances, bringing convenience to daily tasks.

In modern devices, air actuators are compact yet powerful. They can provide haptic feedback in smartphones and tablets. This technology enhances user interaction, making it feel more intuitive. Imagine a smartphone vibrating lightly when you touch specific areas. This could help improve accessibility for many.

Tips: Consider the environmental impact of air actuators. While they offer advantages, they also require energy to operate. Remember that like any technology, they have limitations. Regular maintenance may be necessary to ensure optimal performance. By staying informed, you can make the most of these innovative devices.

Related Posts

-

The 7 Best Air Actuators for Enhanced Performance and Efficiency

-

Revolutionizing Industrial Automation with Cutting-Edge Pneumatic Valve Actuators

-

10 Essential Tips for Choosing the Right Air Actuator for Your Projects

-

How to Choose the Right Pneumatic Valve Actuator for Your Application

-

Exploring Air Actuator Innovations at the 138th Canton Fair 2025 in China

-

Exploring the Future of Pneumatic Control Valves in 2025 Top Digital Innovations