Blog

Essential Tips for Choosing a Pneumatic Butterfly Valve?

Choosing the right pneumatic butterfly valve can significantly impact your system's efficiency. Industry expert Dr. Jane Thornton emphasizes, "The right valve choice is crucial for optimal performance." With the wide variety of options available, making an informed decision is essential.

Many factors contribute to the ideal selection. These include size, pressure rating, and materials used. Each detail matters in real-world applications. A valve that's too small will restrict flow, while one that is oversized may lead to inefficiencies.

Understanding specific application needs is critical. For example, the environment or medium that the valve will control can alter its performance. Some may overlook these details, which can lead to operational challenges. Reflecting on these points can help ensure that your choice aligns with your system requirements.

Understanding Pneumatic Butterfly Valves and Their Applications

Pneumatic butterfly valves play a crucial role in various industries. They control the flow of liquids and gases with precision. These valves are compact and lightweight, making them ideal for tight spaces. According to industry research, the global pneumatic valve market is projected to reach $23.6 billion by 2026, with significant growth in the chemical and oil sectors.

Applications are varied. In wastewater treatment, these valves help manage flow and pressure effectively. This is essential for maintaining system integrity. However, the effectiveness of these valves depends on the proper selection and installation. Many users overlook valve sizing, which can lead to performance issues. The right valve must match the application's specifications.

Manufacturers emphasize the importance of materials used in the valve's construction. Corrosion resistance is crucial in corrosive environments. Research indicates that nearly 30% of all valve failures stem from material degradation. Thus, understanding the operating conditions is vital. Users should also consider the pneumatic actuator's response time. Fast acting components can improve system efficiency significantly.

Essential Tips for Choosing a Pneumatic Butterfly Valve

| Dimension | Material | Pressure Rating | Temperature Range | Actuator Type | Applications |

|---|---|---|---|---|---|

| 2" (50 mm) | Stainless Steel | 150 PSI | -10°C to 80°C | Spring Return Pneumatic | Water, Air |

| 4" (100 mm) | PVC | 100 PSI | 0°C to 60°C | Double Acting Pneumatic | Chemical Processing |

| 6" (150 mm) | Ductile Iron | 250 PSI | -20°C to 120°C | Electro-Pneumatic | Oil, Gas |

| 8" (200 mm) | Aluminum | 200 PSI | -10°C to 90°C | Pneumatic Actuator | HVAC Systems |

Key Factors to Consider When Choosing a Pneumatic Butterfly Valve

When choosing a pneumatic butterfly valve, several key factors should be considered. The first important aspect is the material used. Valves may be constructed from various materials, including stainless steel, cast iron, or plastic. Each material has its strengths and weaknesses. For instance, stainless steel offers high corrosion resistance, while plastic may be lighter and less expensive.

In addition to material, sizing is crucial. Data from industry reports shows that improper sizing can lead to inefficiency. A valve that is too large may lead to flow restrictions, while a smaller valve could cause pressure loss. Always refer to flow data and system requirements for accurate sizing.

**Tip:** It’s essential to check the actuator’s compatibility with your valve. Some actuators may not operate well with all valve types.

Another consideration is the temperature and pressure range. Different valves operate optimally within specific parameters. Keeping these ranges in mind helps avoid operational failures. Ensure the selected valve can handle the maximum pressure and temperature of your system.

**Tip:** Regular maintenance is crucial. Neglecting it may lead to performance degradation over time.

In summary, understanding these factors helps ensure that you make an informed decision. Remember, not all valves are created equal.

Essential Tips for Choosing a Pneumatic Butterfly Valve

This chart illustrates key factors to consider when choosing a pneumatic butterfly valve, with a focus on their importance level rated from 1 to 10 for various parameters such as material, size, pressure rating, temperature rating, and actuation type.

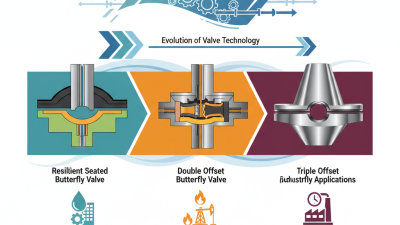

Materials and Construction Types for Durability and Performance

When selecting a pneumatic butterfly valve, materials and construction types are crucial. Valves made from stainless steel offer excellent corrosion resistance. This is vital in harsh environments. On the other hand, plastic options can be light and cost-effective. However, their durability might be questionable in high-pressure situations. Users often overlook how these materials interact with the media being controlled. This can lead to unexpected failures.

Moreover, the construction type plays a significant role in performance. Flanged designs are common but may not suit every application. They require proper alignment and sealing. A wafer-style valve may work better in tight spaces. While these may not integrate as smoothly, they can perform well if installed correctly. The choice depends on your specific application needs. Thinking critically about these options ensures a better fit for your system. Many choose based on price alone, ignoring long-term implications.

Sizing and Flow Requirements for Optimal Operation Efficiency

When selecting a pneumatic butterfly valve, understanding sizing and flow requirements is crucial. A well-sized valve ensures optimal flow rates and prevents unnecessary pressure drops. According to a report by the Fluid Control Association, nearly 30% of valve failures occur due to improper sizing. This highlights the importance of accurately calculating the valve's diameter and flow coefficients.

Flow requirements vary across applications. For instance, a typical industrial system may need a butterfly valve that supports 1300 to 1500 cubic feet per minute (CFM). In contrast, smaller residential setups might only require 300 to 500 CFM. It's essential to match the valve's specifications with the system design. An under-sized valve limits flow and causes inefficiencies, while an over-sized one can lead to turbulent flow and unwanted noise.

Keep in mind that flow characteristics can change with different media. Viscosity, density, and pressure influence how fluids move through a system. Many engineers underestimate these factors. Regular reviews of flow patterns help identify issues earlier. Ultimately, investing time in understanding these parameters will yield better operational efficiency and longevity for the valve in its intended application.

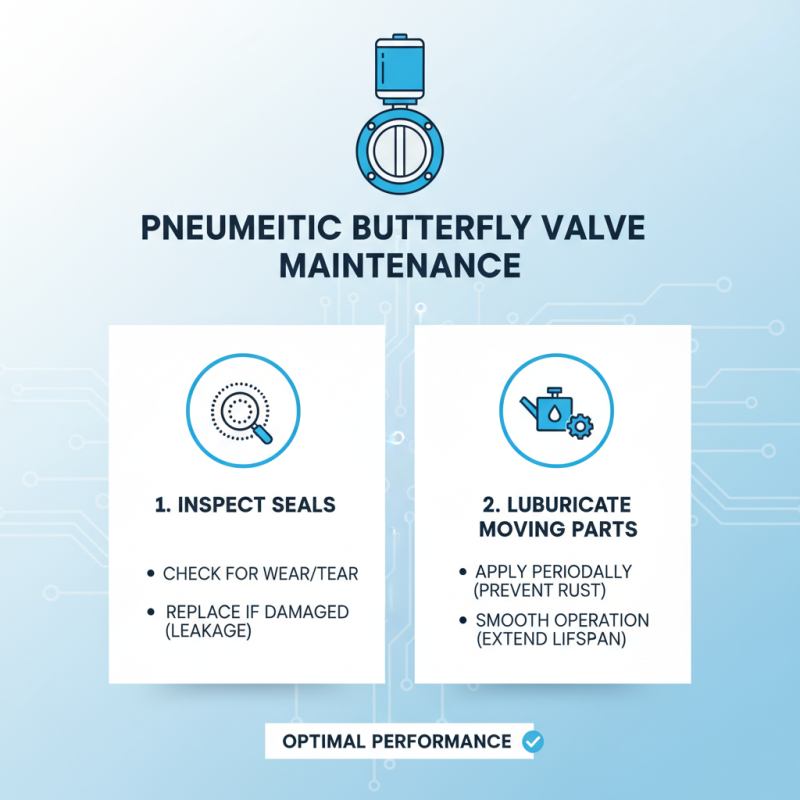

Maintenance and Troubleshooting Tips for Pneumatic Butterfly Valves

Pneumatic butterfly valves require regular maintenance to ensure optimal performance. Inspect seals for wear and tear, as damaged seals can lead to leakage. Replace seals that show signs of deterioration. Additionally, lubricate moving parts periodically to prevent rust and ensure smooth operation. Proper lubrication minimizes friction and extends the valve’s lifespan.

Troubleshooting is equally vital. If a valve fails to close fully, check for debris blocking its path. Dirt can accumulate in the valve and hinder its function. Ensure the pneumatic actuator is receiving the correct pressure. Inadequate pressure could cause sluggish motion.

Consider conducting routine tests. These can catch potential issues early. Sometimes, a valve might operate under varying pressure conditions. This can expose weaknesses. Document any irregularities. Observing patterns can help you understand when a valve is nearing failure.

Related Posts

-

Understanding the Benefits of Butterfly Valves in Modern Industrial Applications

-

Top 5 Types of Butterfly Valves You Need to Know for Optimal Performance

-

Understanding Different Butterfly Valve Types and Their Applications

-

How to Choose a Pneumatic Butterfly Valve for Your Application?

-

How to Choose the Right Basket Strainers for Your Industrial Needs

-

2025 Top 5 Pneumatic Control Valves for Optimal Industrial Automation